Everyone wants to live comfortably throughout the year, staying cool in summer and warm in winter. Yet there's a need to be energy-savvy as well. That's why we make resins that play an important role in home insulation.

Insulating material

In all uses that require insulation, including houses

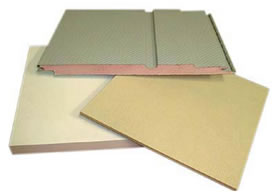

By exploiting the flame- and heat-resistant properties of phenolic resin, we have developed a new type of insulating material, phenolic foam. In short, we have given resin insulating properties by causing it to foam. This phenolic foam is used as insulation in homes. In this way, the release and absorption of heat from the room to the outside can be minimized, thus enabling comfortable living conditions throughout the year. Phenolic foam is being supplied as a material for board-type insulation to many building material manufacturers.

It has diverse applications, including metallic siding, external wall insulation, roof insulation, ceiling insulation, floor insulation, interior partitions (fusuma), ceiling materials, front doors, aluminum sashes, in other words, it can be found everywhere from roofs to foundations. In addition, it is also being used in external wall materials and flooring in general construction, as well as freezers and refrigerators in chemical plants, vehicles, and sea vessels, not to mention refrigerated display cases in convenience stores and wherever else insulation is required.

Two types of insulation that can be selected to suit the site

Phenolic foam combines resins, a foaming agent, and a hardening agent, and is formed into a board by foaming and curing the mixture. It is then installed at the site. Compared with traditional insulation (hard urethane foam, gypsum board, fiberglass), phenolic foam is fire resistant, chemically stable, and combines superior insulation and fire prevention properties. In particular, it is highly incombustible; under the revised certification of building materials, it is classified as a "quasi-incombustible material." we also offer another type of spray-on urethane insulation, the AV Spray System. This type of insulation is sprayed on at the site. It exhibits excellent workability even at low temperatures, and is receiving much attention as a next-generation insulation that can meet a wide variety of construction needs.

Advances made in insulation is a history of comfortable living

It has only been forty years or so since insulation began to be used in homes as a matter of course. Traditional Japanese homes were known to be cool in the summer, but cold in the winter. In the 1950's, the highly flame-resistant gypsum board made its appearance for use in aluminum sash houses, keeping them warm and reducing drafts. Since the oil crisis in 1974, the focus turned to home insulation as a means of conserving energy. Around this time, plastic foams using urethane and phenolic resin were introduced. It was a revolutionary type of insulation that posed no issues of condensation forming inside walls. It also allowed wood to breathe by creating airflow within the walls, thus prolonging the life of wooden houses. Plastic foam insulation enabled the creation of comfortable and healthy houses that could maintain fixed temperatures throughout the year without the worry of condensation.

Positive steps toward environmental measures

We live in a world that demands environmental measures, including the prevention of global warming. Our insulation promotes the efficiency of air conditioning and contributes to an energy-conscious home. We have been one of the first companies to employ systems that do not use fluorocarbons in insulation. Hydrogen carbide and carbon dioxide gas are used as foaming agents in our phenolic foam. In addition, since phenolic foam is a heat-cured resin, it will not easily revert to its original state once it has been transformed into a solid. As a result, interested organizations have begun studying thermal recycling, which makes effective use of the energy emitted during combustion. Currently, we are in the process of creating a recycling system wherein insulation removed during the building demolition is recovered, converted into recycled plastic fuel, and used as solid fuel at steel plants and paper plants.

We are also making other positive steps in environmental issues, including the introduction of material recycling, where a portion of phenolic foam from building materials is pulverized and reused as powder.

Products for construction and civil engineering

Introducing products (such as phenolic foam) for use in construction and civil engineering applications that make use of their flame- and heat-resistant properties.

Click here for resin product information

Other Application Examples