Body from here.

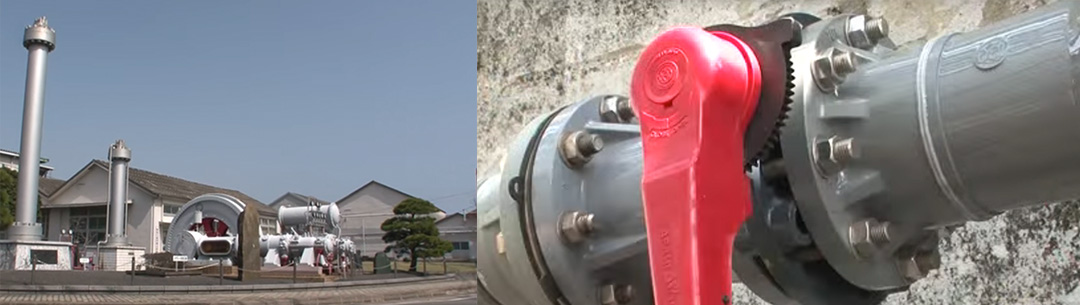

Presenting the advantages of our technologies for the development and improvement of plastic valves and those for polymerization and synthesis of phenol resins that we have cultivated for more than 70 years since our establishment in 1945, as well as the advantages of the water treatment and resources exploitation technologies owned by Drico Co., Ltd., which became part of our Group in 2013

![]()

For chemical fluid lines, metal valves are generally used. However,

metal had a drawback, namely corrosion induced by chemical fluid.

We became the world's first to develop resin valves with chemical resistance and excellent durability.

They were a savior for chemical fluid lines.

Chemical plants produce very strong acid and alkali products.

They impede the use of metal valves.

We find ASAHI YUKIZAI's thermoplastic valves technologically excellent and reliable.

We have adopted ASAHI YUKIZAI's pipes and valves for two reasons. The first is reliability based on its long history.

And the second is the breadth of variety available in terms of size and type.

That means a quick response to our requests.

We hope that it will continue to help us with design and construction in the future.

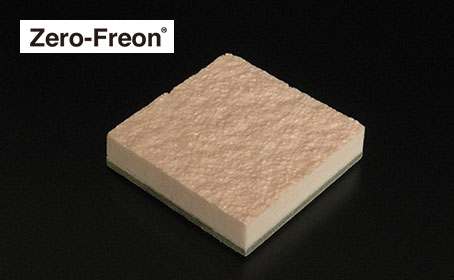

Using our technologies, we took on the difficult challenge of creating heat insulation materials featuring outstanding performance without using chlorofluorocarbons (CFCs), which are known as one of the causes of global warming. We focused our attention on polyurethane foam.

It can be relatively easily produced and its characteristics vary depending on the formula and production method.

In 2009, we thus released the Zero-Freon®. This CFC-free system exhibits such a high level of heat insulation performance that its global warming potential is about one-thousandth that of CFCs.

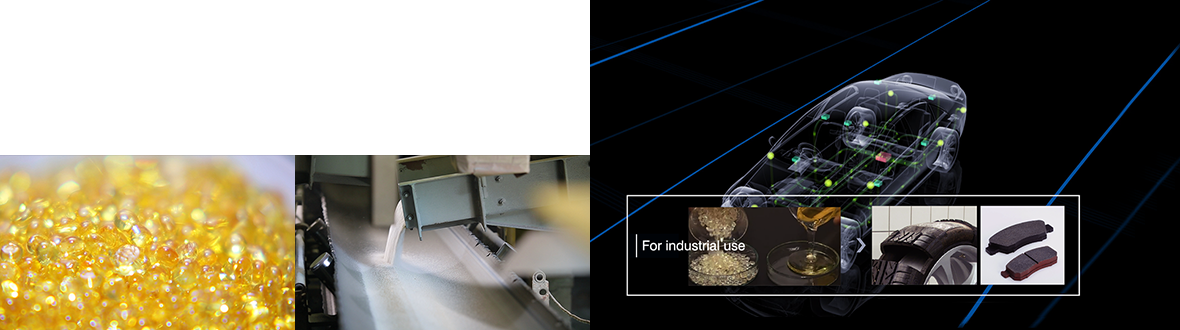

We have been untiringly pursuing the potential of phenol resins. As early as the 1990s, we were paying

attention to their potential in electronic material applications.

We built a dedicated plant for these products in 2001 and since that time have been producing resins for

semiconductors and LCDs based on processes designed to minimize metals contamination.

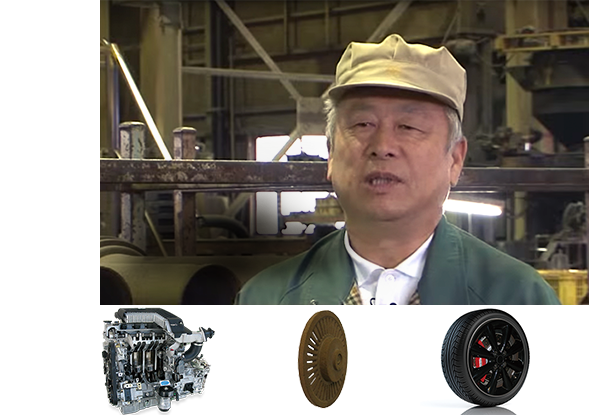

We are Japan's largest manufacturer producing both foundry resins and resin-coated sand. We applied the characteristics of phenol resins, such as heat resistance and wear resistance, to refractory bricks, tire materials and molding materials for automotive components.

As you know, cars carry human lives.

They are required to provide perfect safety.

ASAHI YUKIZAI's resins have great performance helpful to producing high-precision castings such as engines.

We view them as the industry leader.

We have found ASAHI YUKIZAI to be absolutely reliable and have enjoyed a long-term relationship with them.

We have developed a system that collects and treats wastewater from urban commercial buildings for reuse. We contribute to the global environment and people's lives by achieving the effective use of water resources.

Technologies for excavation have paved the way for actively using water heat resources in medical care, welfare and other new fields.