What is a piping check?

Made not only of plastics but of many other materials, piping materials do not have infinite durability, and deterioration due to aging may give rise to serious failure. To keep piping equipment in good condition, it is vital to grasp its state accurately and to take appropriate steps. Based on its advanced technical capabilities and ample track record of checking lines for hydrochloric acid, caustic soda, hydrogen peroxide, nitric acid and many other chemical fluids, our piping check supports customers’ equipment management.

Check item

| Observation of interior and exterior | ○ | Checking whether there is any discoloration or other changes caused by light, heat, moisture and so on |

|---|---|---|

| Observation of pipe wall thickness on cross-section | ○ | Measuring the depth of deterioration (discolored portion) |

| Tensile strength | ○ | Measuring the retention of tensile strength with respect to unused products |

| Tensile elongation | ○ | Measuring the retention of tensile elongation with respect to unused products |

| Impact strength | ○ | Measuring the retention of impact strength with respect to unused products |

| Report creation | ○ | Reporting the check results |

| Composition analysis | Option | Performing an electron probe micro analysis (EPMA), observation with a scanning electron microscope (SEM), and an analysis with fluorescent X-rays |

| Technician dispatch | Option | Technical staff visit customers' premises to perform on-site checks and provide on-site explanations |

- Composition analysis

EPMA and observation with SEM…Qualitative and quantitative analysis of constituent elements by electron irradiation and observation of the surface and crack status

Analysis with fluorescent X-rays…Qualitative and quantitative analysis of constituent elements by X-ray irradiation

- *The check items mentioned above are covered as standard. Check items may be selected upon request.

- *We will quote the cost.

- Rough guide to the check period

-

Approx. 2 weeks for one specimen

Approx. 3 weeks for five specimens

Approx. one month for composition analysis*The check period may vary depending on the amount of order we have received.

- Samples required for the check

- 13 to 30A…500mm or more

40 to 65A …300mm or more

75A or more…200mm or more

If additional composition analysis is to be conducted, an extra 100 mm is required.*For a check on any product other than pipes, contact us separately.

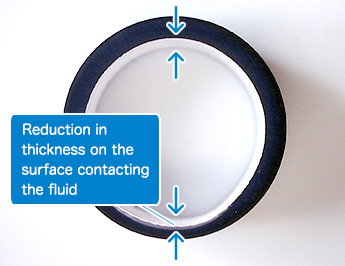

Example of deterioration

Reduction in thickness

In this example, erosion caused by the fluid reduced the wall thickness of the pipe and resulted in leakage.

Permeation

In this example, the chemical fluid permeated the pipe and seeped out onto the external surface.

Damage following material deterioration

In this example, the piping, which was severely deteriorated by the chemical fluid, was unable to withstand the stress and cracked.

Track record

Rich experience in checks underpins its reliability.