Pine Industrial Materials Co., Ltd. (PIM) is a Thailand-based company that aims to be the world’s top producer of resin-coated sand for foundries. Since its establishment in 2005, PIM has worked in collaboration with ASAHI YUKIZAI to leverage state-of-the-art production processes. Managing Director Ithinai Yingsiri spoke to us about how they deliver market-leading quality for their customers in Thailand and beyond.

From Humble Beginnings to Market Leaders in 10 Years

Our roots go back to 1989. In that year, our parent company, PINE-PACIFIC, was founded as a trading firm that imported raw materials from countries such as Japan, China, and the UK, then supplied them to foundries in Thailand for use in casting. Over the following decade, it became clear that there was a need to expand the scope of the business to include production and engineering. We established Pine Industrial Materials Co., Ltd. (PIM) in 2005 as a new company to drive the production of reclaimed sand and resin-coated sand (RCS) for foundries.

One example to demonstrate the scale of the potential business opportunity is Thailand’s motor vehicle manufacturing industry, which was one of the world’s largest at the time and has grown since. Today, Thailand is among the top ten automobile-producing countries, manufacturing around two million vehicles per year. Vehicle manufacturers are major clients for foundries, and those foundries need raw materials. We knew we had a significant potential customer base, but we were more or less starting from scratch. This was also a major undertaking that posed massive technical challenges. To make our vision a reality, we sought to collaborate with a partner that had the required technical capabilities and a strong track record in the field.

In 2005, ASAHI YUKIZAI had already built up about 50 years of experience and expertise in the industry. In addition to having a well-established presence, their production and quality assurance processes made them a market leader in terms of quality. Another key point for us was the importance they place on continuing to improve through ongoing research, development and innovation.

ASAHI YUKIZAI produces resin to an exceptionally high standard and has provided us with extensive technical support from day one. As a result, we were able to make RCS as strong as our competitors’ products while using lower resin content. Combined with the fact that ASAHI YUKIZAI’s resin produces less gas than competing products when using the same amount of resin, this enabled us to deliver products that support casting with fewer defects. With this quality as a key differentiating factor, we had an immediate impact in the market. Within just ten years, we went from zero sales to market leaders.

As a market leader, PIM has developed efficient, adaptable logistics systems to meet wide-ranging customer needs while preserving product quality in Thailand’s hot climate.

As a market leader, PIM has developed efficient, adaptable logistics systems to meet wide-ranging customer needs while preserving product quality in Thailand’s hot climate.

Quality Built on Close Cooperation

ASAHI YUKIZAI is a reliable partner that has delivered comprehensive support ever since PIM was established twenty years ago. In terms of technical cooperation, they provided all the information we needed to begin setting up our production processes. Today, our factory in Thailand continues to reap the benefits of ASAHI YUKIZAI’s 80 years of know-how. A key factor in ensuring effective collaboration has been the presence of a technical coordinator on the ground in Thailand for the last 20 years. This has enabled the two companies to constantly update each other on technical and business matters. The direct support from ASAHI YUKIZAI is important not only in terms of production, but also in other areas. For example, we have many Japanese customers, and our technical coordinator gives us valuable insight from both business and cultural perspectives to enable us to better meet their needs.

Through the complete package that ASAHI YUKIZAI provides, in addition to having access to market-leading resin and production processes, we have the technical know-how to effectively leverage these assets to make a difference for our customers. We also have the peace of mind of having a technical coordinator on hand to help us immediately address any issues that may arise.

.re.jpg) Close cooperation is key to PIM’s partnership with ASAHI YUKIZAI. Having a technical coordinator from Japan on the ground in Thailand facilitates seamless, agile communication.

Close cooperation is key to PIM’s partnership with ASAHI YUKIZAI. Having a technical coordinator from Japan on the ground in Thailand facilitates seamless, agile communication.

Always Evolving to Stay Ahead of the Pack

ASAHI YUKIZAI’s commitment to constant improvement was a key factor in our decision to work with them two decades ago. While we have achieved great things so far, our competitors are also striving to improve, so standing still isn’t an option. This is particularly true for us, because market-leading quality is core to the value that we deliver to our customers—competing on price alone is not in line with our business strategy. ASAHI YUKIZAI is always innovating and improving their processes and products, making them an ideal partner in this regard.

We have worked hard to establish a leading position in the Thai market, and continuing to innovate together will be key to building on that strong position. Having a direct point of contact on the ground in Thailand ensures a constant channel for effective coordination, and enhancing this communication further in the future will be even more important in driving new advancements that align with the needs of our customers.

ASAHI YUKIZAI has always been proactive in proposing and implementing new innovations. For example, about five years ago, they introduced a new type of RCS, called Hexapass, for use in our products. This RCS produces less gas and odor than previous products when using the same amount of resin. As a result, the amount released during casting processes is reduced. Not only does the reduction of gas increase the quality of the resulting end products, but the odor-reducing effect also helps to mitigate the impact that foundries have on surrounding communities. In this way, ASAHI YUKIZAI took the initiative in putting forward a solution that addresses key challenges faced by our customers on a daily basis.

This production line recycles customers’ waste sand into high-quality reclaimed sand for use in RCS. In addition to this recycling of a waste byproduct, heat generated during roasting is reused to dry sand, further reducing environmental impact.

This production line recycles customers’ waste sand into high-quality reclaimed sand for use in RCS. In addition to this recycling of a waste byproduct, heat generated during roasting is reused to dry sand, further reducing environmental impact.

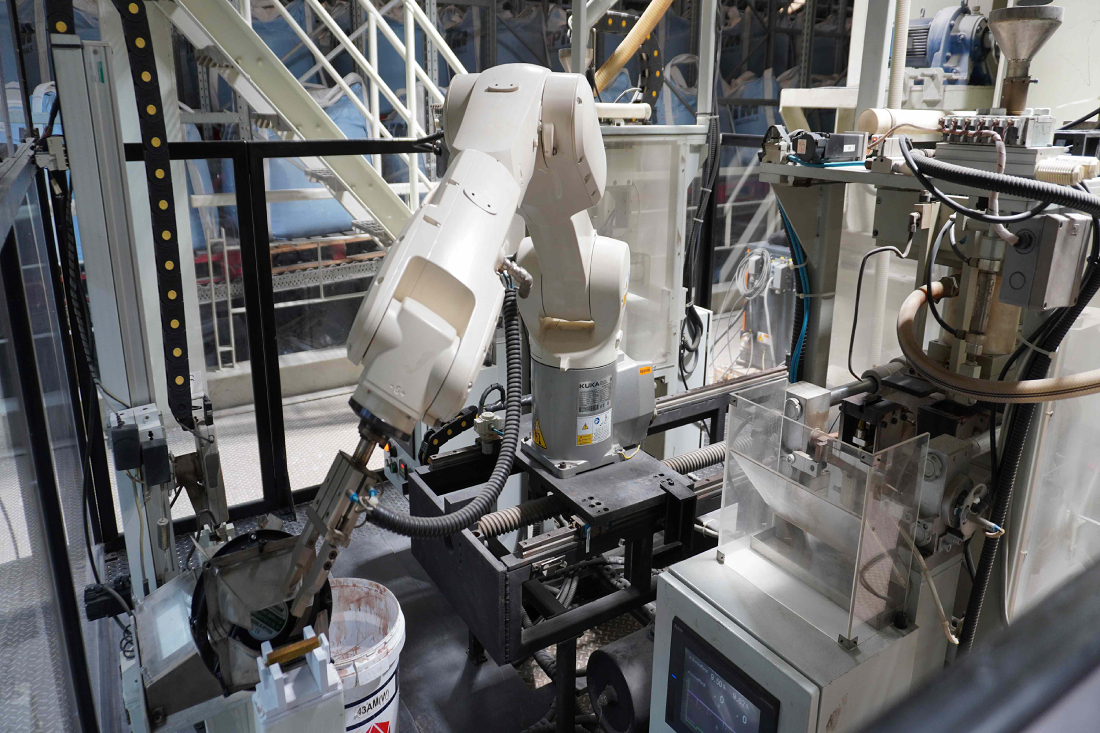

PIM uses equipment such as this automatic bending strength measurement device to ensure all products meet exacting standards.

PIM uses equipment such as this automatic bending strength measurement device to ensure all products meet exacting standards.

Our partnership with ASAHI YUKIZAI has enabled us to achieve remarkable growth from the outset of our operations. We have worked together to build on that strong foundation and firmly establish ourselves as Thailand’s leading provider of foundry sand and RCS. I look forward to carrying on this collaboration in the pursuit of ever-improving quality as we strengthen our relationships with existing customers and expand to grasp new opportunities.