Introduction of the HexaPass®, a brand-new RCS that reduces odor generated in the casting process

Overview

Forming and casting in the shell mold method generates phenols, formaldehyde, ammonia and amines to produce a peculiar odor. Efforts had long been made to suppress the odor but the conventional low-odor RCS had some drawbacks, such as insufficient reduction of the odor level and a low hardening velocity, which meant a long forming time and poor productivity.

HexaPass® is a new type of RSC that has resolved these issues. We have developed a hardening mechanism free of hexamine, which caused the foul odor, to significantly lower odor and smoke levels. It also achieves a hardening velocity equivalent to the conventional hardening method using hexamine to ensure mold production in a forming time equivalent to that with the general type of RCS. In addition, the quality of hollow cores produced in the reverse sand elimination method has improved

Forms

- Sand

Features

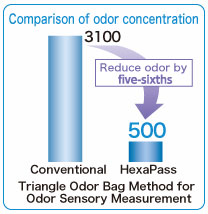

Odor concentration reduced with a hardening mechanism independent from hexamine

- Low odor: The odor level measured in The triangle odor bag method fell to around one sixth The level with The conventional RCS (hexamine hardening)

- Low irritation: Generation of irritant ammonia and formaldehyde massively cut

- Low smoke: smoke Generation reduced at The time of forming

- Resistant to peel back: Padding reduced in hollow core production by The reverse sand elimination method

- Low gas emission: gas emissions reduced from The conventional RCS with The same amount of resins

- Quick hardening: The same forming cycle as that with The conventional RCS maintained